High Capacity Sand Buckets

Empire’s High Capacity Sand Buckets will improve your productivity and reduce your need for wear part replacement! Designed for glacial sands these buckets dig into the soil like a spoon digging into ice cream. The beveled edge slices through without the need for expensive ground engaging tools (GET). Sand buckets use Hardox 450 wear plate in all the ground engaging parts of the bucket to provide you with up to 3 times the life of the bucket shell compared to other bucket manufacturers. There are three main types of Empire Sand Buckets. Please see the individual bucket specification pages for additional information.

HCRB – High Capacity Round Bottom

HCRB – High Capacity Round Bottom buckets are for sewer or pipe work. The radius shape of the cutting edge slices through the soil easier than typical “digging” buckets because there is less soil contact area. The larger capacity of Empire’s Sand Bucket allows you to move more soil per cycle and make more profit per year. The round bottom radius design requires less bedding materials than typical excavator buckets.

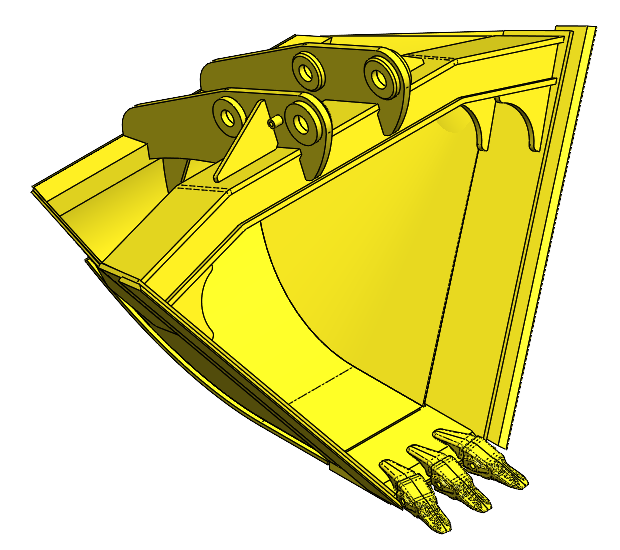

FBRC – Flat Bottom Round Corner

Empire’s High Capacity FBRC Sand Bucket is our most popular design! This bucket can be used for top loading materials and general excavation work. The Hardox main blade has a beveled leading edge to slice through soil easily. The larger capacity of Empire’s Sand Bucket allows you to move more soil per cycle and make more profit per year!

FBSC – Flat Bottom Square Corner

Empire’s High Capacity Flat Bottom Square Corner Sand Bucket is designed for footing and basement work. A replaceable bolt on cutting edge (BOCE) is usually added to this bucket style for grading or excavation work. The Hardox main blade has a beveled leading edge. The larger capacity of Empire’s FBSC Sand Bucket allows you to move more soil compared to typical OEM GP buckets.

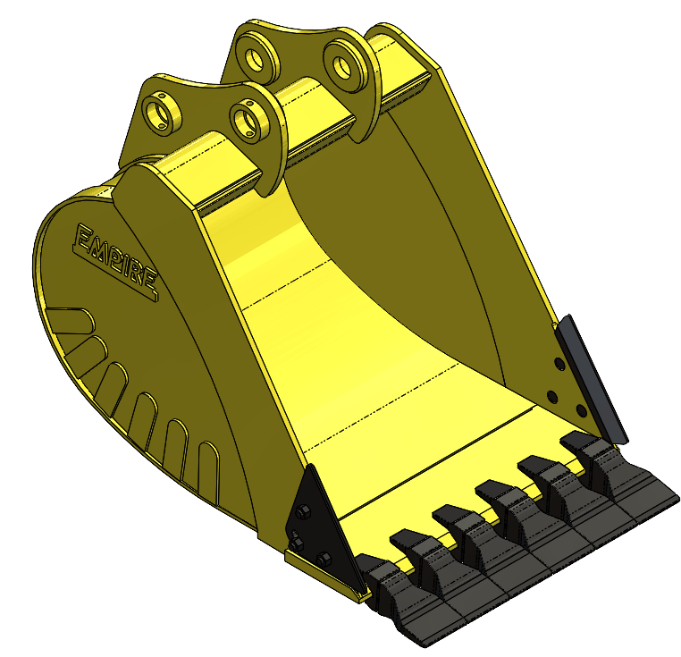

General Purpose / Tooth Buckets

Empire offers four different grades of General Purpose (GP) buckets to match your bucket to your specific needs. The groups are based on the bucket’s intended use in selected materials. Optional for all GP buckets are Welded-on Adapters with Teeth or a replaceable BOCE. Buckets can be machined for your choice of Side Cutters or Slack adjuster.

General Duty GP Buckets

Designed for digging in less abrasive materials such as dirt, loam and mixed compositions of dirt and gravel. Empire typically would recommend a FBSC or FBRC bucket for this application, since the capacity of the bucket would be larger than the standard OEM GP or “Digging” Buckets. This style GP will use standard adapters and teeth, T-1 steel for the main blade and cutting edges.

Black colored items indicate Cast wear components.

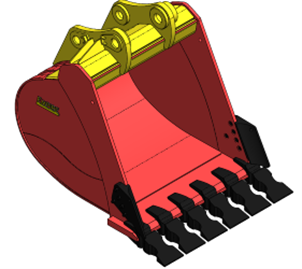

Heavy Duty GP Buckets

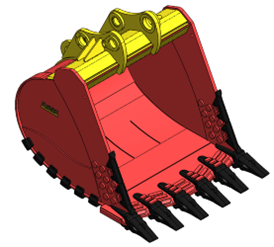

Heavy Duty GP Buckets are Empire’s most popular GP Style. Use when digging in a broad range of materials including dirt, clay and rock. Compared to our General Duty buckets, the Heavy Duty bucket is built using Hardox 450/500 abrasion resistant steel in the cutting edges, sides and bottom. Adapters and Teeth can be up-sized for your specific application.

Black colored items indicate Cast wear components, Red colored items indicated Hardox 450 or 500 wear plate.

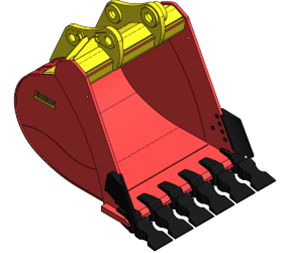

Severe Duty GP Buckets

Severe Duty GP Buckets are for higher abrasive materials such as rock, granite, or quartz. The Hardox bottom and sides are 40% thicker than our Heavy Duty GP buckets. The Hardox Cutting Edges are also thicker to increase protection against abrasion and gouging wear. The Severe Duty GP will use larger adapters and teeth, and can be machined to accept side bars or side cutters.

Black colored items indicate Cast wear components, Red colored items indicate Hardox 450 or 500 wear plate.

Extreme Duty GP Buckets

Extreme Duty Buckets are for very abrasive conditions such as mining quartz or granite. The Extreme Duty GP bucket includes all of the Severe Duty upgrades, plus bucket liners, larger side wear plates, side bar protectors and adapters sized for this application. Corner or heel shrouds, base edge protectors, segments and mechanically attached wear plates can be added to help protect the bucket from wear.

Black colored items indicate Cast wear components, Red colored items indicate Hardox 450 or 500 wear plate.

Special Application Buckets

Whether you’re demolishing pavement, grading, cleaning ditches or working in winter frost, Empire has the bucket you need! Empire manufactures almost any type of bucket needed to help you complete your job! Check out the bucket types below for further details:

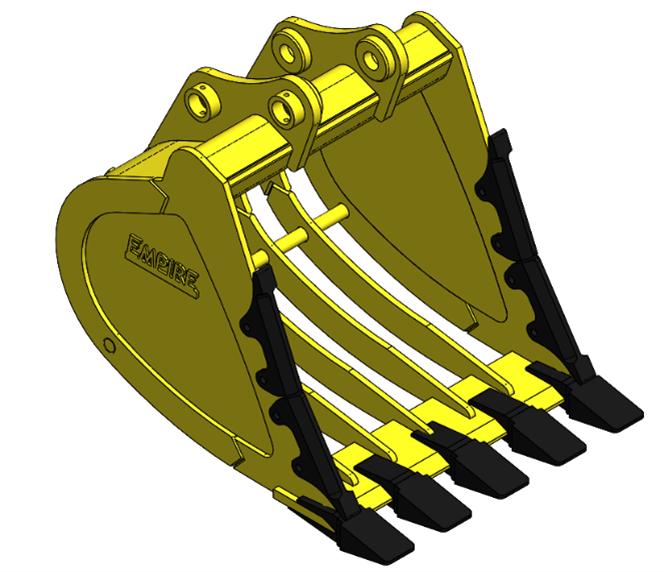

Skeleton Buckets GP Buckets

Designed for digging in rock, Skeleton buckets will help separate loose rock from other soils, or can be used for working with rip-rap in soil erosion control projects. Built using abrasion restistant Hardox steel and designed for easy dumping of rock. These can be equipped with your choice of teeth or BOCE, Tine Spacing of either 4” or 6” depending on materials being sorted.